Reducing the production cycle time

CHALLENGE

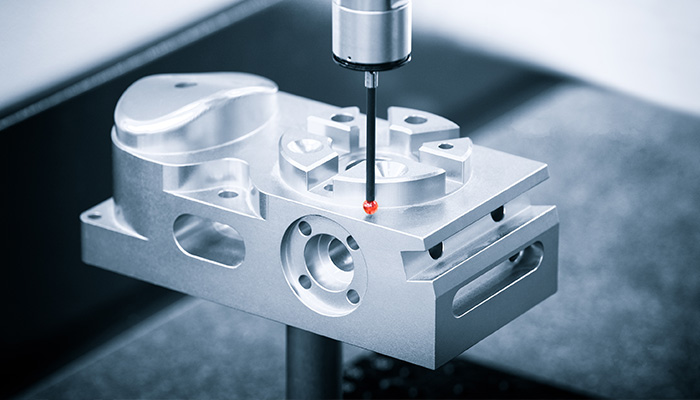

Leading manufacturer of customised precision parts

- Complex production process comprising multiple process steps across various pieces of equipment.

- Product quality is made by the first process step, but can only be determined at the last.

- This feedback cycle (i.e., the production cycle) needs to be quicker to prevent production losses.

Reduce the production time by 50% from 4 to 2 weeks.

The company is highly skilled in Six Sigma, which had already helped them to reduce the cycle time from 11 to 4 weeks. However, the traditional Six Sigma suite of tools could not help them any further.

APPROACH

- The first action was to analyse the production with process mining: Huge variations in takt times between workstations were uncovered.

- Workstations were recombined to rebalance the takt times: A consequence was that the heartbeat of the subcontractor’s process had to be synchronised.

- Further, the available time for preventive maintenance increased.

50% reduction in production cycle time, from 4 weeks to 2 weeks.

More time for preventive maintenance.

Financial savings.

Reduced risk profile as the feedback cycle was reduced