Strong surge in demand causes problems

CHALLENGE

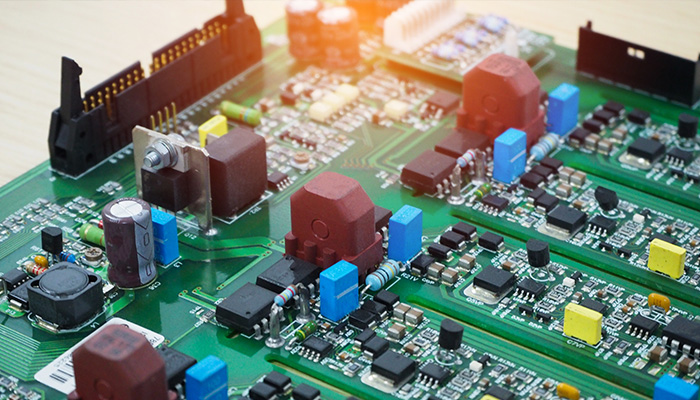

Our client was a Europe-based company developing and manufacturing key electronic components for customers in the consumer electronics; based mainly in Asia.

They were in the ramp-up phase of a new product, and growth was explosive. However, they were suddenly confronted with catastrophic product failure affecting 40% – 60% of the production output.

APPROACH

With senior management we worked on strategic and operational alignment with global market conditions. Together with cross-functional / level teams, we set an aggressive 23-week action plan for bringing production under control.

In production, we focussed on solving the quality problems, increasing the availability of production equipment and improving delivery reliability.

Through collaboration and knowledge transfer, we ensured that employees were empowered and accountable for the delivery of their improvement areas. We helped them to apply the relevant tools they had been trained apply in a skilled manner.

Together with the teams we introduced a new Performance Management System to support their new ways of working. By involving employees in the design, they developed a strong co-ownership of the changes, their unit and its results.